KSO Edelstahlbeizerei

KSO Edelstahlbeizerei GmbH • Essener Straße 16 • D-57234 Wilnsdorf • P: +49 (0) 27 39 87 07-80 • Mail: michael.bode@kso-beizerei.de

We make stainless steel special. KSO

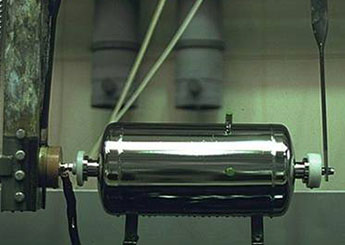

KSO Edelstahlbeizerei GmbH based in Wilnsdorf – in the border region of North Rhine-Westphalia, Hesse and Rhineland-Palatinate – has some of the most modern and state-of-the-art designed stainless steel pickling plants. KSO’s capacity enables components to be machined up to a length of 60 metres and a weight of up to 50 tonnes.

Certification of confidence and reliability

Companies that have metals refined at a stainless steel pickling plant have to be able to rely on the fact that both its employees and production processes meet the quality standards that are stipulated in the relevant norms. Of particular importance in this respect are QM in accordance with DIN ISO 9001:2015 and the environmental management system in accordance with DIN EN ISO 14001:2015. KSO Edelstahlbeizerei GmbH is certified to both standards as well as to DIN EN ISO 45001:2018.

THE COMPANY.

KSO Edelstahlbeizerei

We are constantly developing new applications and processes which make the properties of metals ideally usable for your requirements – and create added value for your company. As an independent, reliable medium-sized company we are proud of our long-standing and trusting relationships with our customers – in Germany and throughout the world.

PLEASE CONTACT US IF YOU HAVE ANY QUESTIONS

Our Products and Solutions

Products and Solutions combined with over 20 years of experience: KSO-Edelstahlbeizerei

Quality & Environment

KSO is certified in accordance with DIN EN ISO 9001, DIN EN ISO 14001 and DIN EN ISO 45001:2018.